Cost-Effectiveness of Compression Molding is Dependent on Accuracy of the Mold

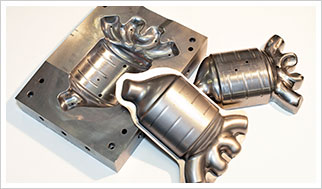

In its basic definition, Compression Molding is a forming process whereby a substance or material is placed directly into a heated metal mold then subjected to high pressure in order to produce a pre-defined shape. This method of production was originally developed in an effort to replacing heavier metal parts with lighter yet durable composite parts/components.

There are several important factors that must be considered for Compression Molding to be most effective; these include:

- The precise amount of material

- The time required to heat the material

- The energy needed to heat the material

- The most appropriate heating method/technique

- Designing the mold for rapid cooling after compression

The Compression Molding process is often considered to be less expensive than other types of molding. As it permits a consolidation of parts and produces less waste/less material loss. Additional reasons for manufacturers to use this methodology would include the following:

- Lower initial set-up costs; faster set-up times

- Ability to produce larger, more complex parts

- More suitable for smaller production quantities

- Fewer seams/joints – more aerodynamic parts

Compression Molding can be utilized to generate custom molded plastic or rubber parts in a variety of shapes and sizes; types of products for which this process can be applied include such examples as:

- Electrical insulators

- Vehicle body panels

- Household appliances

- Acoustical pads and panels

- Fasteners (buckles, buttons)

In order for a manufacturer to fully capitalize on the operational or financial benefits derived from Compression Molding. It will be vitally important to use molds that are highly accurate in design. It is only reasonable to assume that poorly-made molds will generate mediocre and imprecise parts which in turn can/likely will be rejected by customers and/or end-users.

Consequently, manufacturers would be well-advised to consider the precision mold-making services of the experts from Noble Precision as a means of avoiding the potential for such a negative impact on company reputation and revenues.

Precision Compression Molding Services to Optimize Manufacturing Efficiencies

Noble Precision offers the capability to create precision molds for the production of parts or components ranging from smaller commercial items to large panels for automobile and aircraft bodies. Such expertise is supported by Noble Precision’s substantial investments in state-of-the-art technology. Most notably the latest in 5-axis simultaneous CNC machines and CAD/CAM software. Thus allowing their clients to be beneficiaries of the most advanced and accurate machining methodology currently available.

Additionally, Noble Precision’s experienced designers can produce molds to meet production specifications for the following types of materials used in the Compression Molding process:

- Thermoplastics

- Uncured rubber

- hermoset plastics

These precision molds created by Noble Precision can assist clients in achieving the highest possible manufacturing efficiencies. Including time and cost savings, reduction/elimination of waste, and high tolerances. To obtain more information on the precision molding services offered by Noble Precision, see our Mold Making page.

For precise Compression Molds to support the production of high-quality and high-tolerance custom molded plastic or rubber parts/components. Call the specialists from Noble Precision at 647-499-7569 or contact usto request a complimentary consultation.