From intricate components to large complex machines, creating a prototype helps test your idea’s real-world functionality. Doing this will not only proof your concepts but also ensure that your money is well invested. Our rapid prototyping OCAD experts offer a few useful tips on how to efficiently develop your idea and bring it quickly to the market.

Tips for Successful Prototyping

There is no single prototyping method for all types of models. These are general guidelines to proof new ideas, identify and correct problems in the early stage, as well as estimate your production and development costs.

- Build a few rough models first: The goal of prototyping is to test whether your idea works. This means your initial DIY model does not have to look perfect. Use inexpensive items you can find in your workshop to quickly create a few mock ups. It will save you time and money.

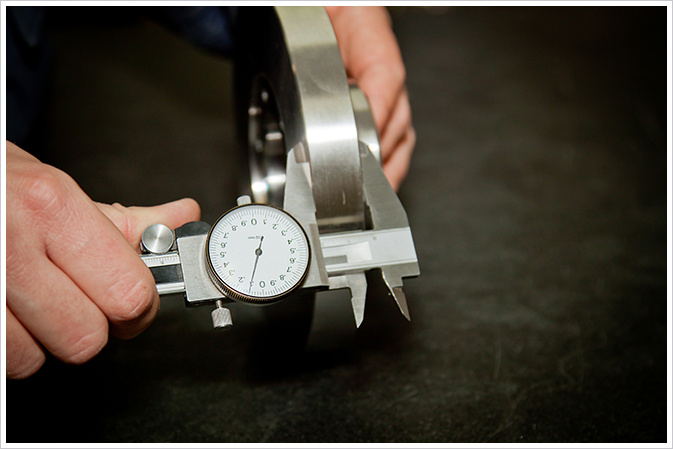

- Take your concepts to a prototyping company: Once you have a few concepts to work with, consult design-build engineers about troubleshooting and testing your proofs. Choose a reliable Toronto prototyping company that offers fixed costs and some flexibility with making changes during the product development stage. Working with your manufacturer from the design stage can help eliminate or reduce the risk of rework. Pay attention to their technology and machinery. Advanced equipment and proven processes will aid in improving speed, precision and quality.

- Outsource your R&D: You cannot sacrifice design for functionality or vice-versa. Achieving the right balance of aesthetics and functionality is critical to maintaining a healthy bottom line. Outsourcing your R&D can be cost-effective as you may not have the design and manufacturing expertise in-house (or need to incur the additional staffing cost). Give the prototyping engineers guidelines on which features are important and those that can be eliminated. Some companies offer budgetary forecasts based on different models, which allows you to choose more economical alternatives. Designing for manufacturability can optimize many functions of your product development process, including fabrication, assembly, test, procurement, shipping, delivery, service, and repair.

- Keep the customer in mind: Meeting your customers’ needs is key. Customer surveys during the R&D phase as well as product testing once your prototype is ready, are instrumental to the success of your product. Remember that if customers do not like it, they will not buy.

Reduce Time to Market with Noble Precision’s Rapid Prototyping Service

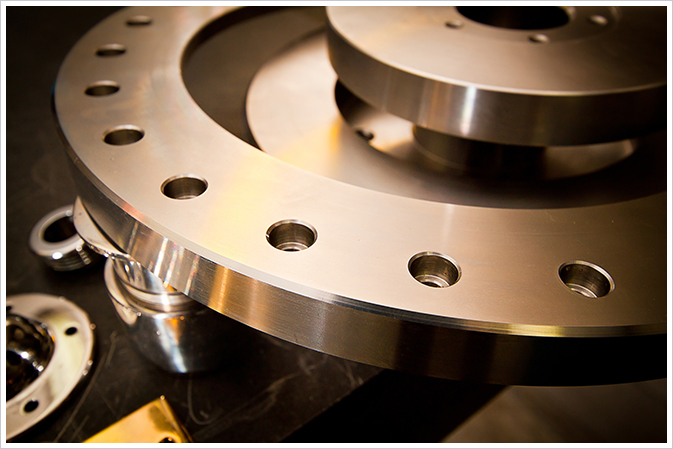

Rapid prototyping solutions at Noble Precision help test your product quickly, and serve to keep your cost down. From conceptualization to precision manufacturing/assembly, and rigorous testing and quality assurance, we are fully committed to ensuring that every prototype meets your exacting specifications. Together with our sophisticated rapid prototyping OCAD, 5-axis simultaneous CNC machine technology, and cooperative engineering support, you can improve your position in the market, and your bottom line. Aviation, aerospace, electronics, automotive, heavy equipment, mining, and transportation manufacturers are just a few of the clients that have taken advantage of our high-quality axis prototypes.

Contact Noble Precision for a no-obligation quote. You can reach a team member at 416-938-6455 or contact us online with your questions about our rapid prototyping services.