Cutting-Edge Technology: Multi-Axis Simultaneous CNC Machining and Its Benefits

When it comes to working with different types of metals, the processes of parts fabrication and metal removal have advanced greatly from the days of manually-operated machinery. What were once felt to be somewhat protracted and inexact procedures have now become much more efficient and highly precise manufacturing methods.

When it comes to working with different types of metals, the processes of parts fabrication and metal removal have advanced greatly from the days of manually-operated machinery. What were once felt to be somewhat protracted and inexact procedures have now become much more efficient and highly precise manufacturing methods.

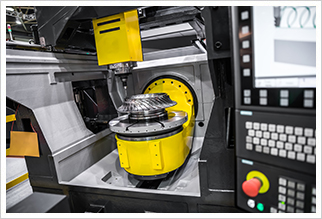

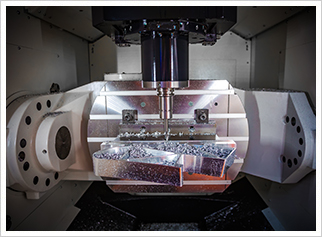

The advent and proliferation of computer numerical control (or CNC) machines has clearly transformed the manufacturing of many metal products; this technology, which includes multiple-axis simultaneous machining that is operated or controlled by specialized computer software, now permits the manufacturing of parts and components that were once deemed to be highly impractical from the standpoints of size, time, and/or cost.

This cutting-edge CNC machining technology requires just a single set-up for simultaneous milling and drilling of parts/components along multiple axes; it has consequently improved the metal removal and metal manufacturing processes in several ways:

- Faster cycle times

- Superior cost efficiency

- Reduced production times

- Accelerated delivery times

- Improved quality/tolerances

- Many tools working concurrently

The most common types of CNC Machinery and their primary applications include:

- 5-axis – CNC machining is done along three perpendicular axes and two rotary axes

- 6-axis – CNC machining is done along three perpendicular axes and three rotary axes

- Lathes – for production of 3D shapes/molds; automatically programmed tool changes

- Routers – used for cutting complex/intricate shapes and prototypes from metal sheets

- Milling – most widely used CNC machines; predominantly for drilling and turning metals

- Plasma Cutters – utilized for cutting 2D shapes and molds; need less power than routers

- Laser Cutters – operate similar to plasma cutters, using a laser instead of a plasma torch

Noble Precision has invested significantly in these technologies in order to give their clients access to the broadest possible range of precision manufacturing solutions. Through their applications of 5-axis and 6-axis simultaneous CNC machining, and the various other types of CNC machinery, Noble Precision is able to deliver the most precise fabrication of complex and/or large-scale metal parts, components, molds, and prototypes – and in a cost-efficient manner.

Noble Precision has invested significantly in these technologies in order to give their clients access to the broadest possible range of precision manufacturing solutions. Through their applications of 5-axis and 6-axis simultaneous CNC machining, and the various other types of CNC machinery, Noble Precision is able to deliver the most precise fabrication of complex and/or large-scale metal parts, components, molds, and prototypes – and in a cost-efficient manner.

To learn more about the advantages of multi-axis CNC machining technologies, please visit our Advantages of Multi-Axis CNC Machining page.

CNC Machining Services for Practical Solutions to Precision Manufacturing Needs

The CNC machining services offered by the specialists at Noble Precision can be applied with a variety of metals, including:

- Zinc

- Brass

- Copper

- Titanium

- Aluminum

- Stainless Steel

- Galvanized Steel

As a result, Noble Precision offers the capability to meet the precision metal manufacturing needs, ranging from prototypes to high-volume production runs, of companies that compete in or supply parts/components to industries that include but are not limited to:

- Aviation

- Aerospace

- Automotive

- Construction

- Transportation

- Military Defense

- Home Appliances

- Medical Instrumentation

For more information on Noble Precision’s capabilities relative to precise CNC machining, visit our CNC Machining Technologies page.

The CNC machining services available from Noble Precision can provide practical solutions to complex precision metal manufacturing needs. Call the multi-axis CNC machining experts from Noble Precision today at 647-499-7569 or Contact us to schedule a consultation on the full scope of our capabilities.