Gun Drilling Produces Deep Holes Beyond the Limits of Conventional Twist Drills

The term gun drilling originates from the era when gun manufacturing included boring holes in solid rolls of steel in order to produce the barrels. This would likely have been a laborious task, not to mention potentially suspect in terms of its effect on a weapon’s firing accuracy.

The term gun drilling originates from the era when gun manufacturing included boring holes in solid rolls of steel in order to produce the barrels. This would likely have been a laborious task, not to mention potentially suspect in terms of its effect on a weapon’s firing accuracy.

Today, while the name remains unchanged, the process of gun drilling has developed into a very practical and efficient methodology for boring holes of varying depth and diameter into several types of hardened materials, including:

- Steel

- Plastics

- Titanium

- Aluminum

- Other Ferrous and Non Ferrous Alloys

In the gun drilling process, the cutting tool, or gun drill bit, is in effect a fluted solid rod that has a hole bored lengthwise through its center and grooves along the length of its exterior. As a drilling operation proceeds, coolant is pumped through the central hole to facilitate the movement of the bit while also removing/flushing chips away from the cutting face through those external grooves.

As an aside, this gun drilling technology should not be confused with the single-tube system (known as STS) in which coolant is introduced around the outside of the cutting tool/bit and the chips are removed through the center of the tool. In this respect, STS systems can be described as the inverse of gun drilling. It should also be noted that STS is often referred to as BTA drilling, derived from the Boring and Trepanning Association that initially developed this particular methodology.

Some of the more common applications for Gun Drilling include the production of:

- Various firearms

- Special molds and dies

- Medical and surgical devices

- Woodwind instruments (bagpipes)

- Engine parts (crankcase, cylinder head)

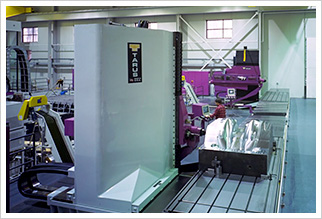

Gun drilling machinery is designed and constructed to produce deep holes beyond the limits of conventional twist drills; through the use of multi-axis Computer Numeric Control (CNC) drills, precision manufacturing services providers such as Noble Precision in Toronto can effectively apply this process to drill holes up to 96” in length and up to 3” in diameter.

Multi-Axis CNC Gun Drilling to Support Complex Precision Manufacturing Needs

Noble Precision’s substantial financial investment in state-of-the-art technology, including its multi-axis CNC horizontal gun drilling machines, enables clients to achieve viable and highly cost-effective manufacturing solutions across an extensive array of deep-hole drilling needs. These precision gun drills can produce holes in much greater depth-to-diameter ratios than conventional twist drills; furthermore, the output from Noble Precision’s gun drilling services will include bores/holes that are:

- Burr-free

- Smooth-finished

- Precisely centered

- Delivered with high tolerances

- Produced to exact specifications

Based on the broad scope of its gun drilling capabilities, Noble Precision can help support the deep-hole drilling requirements of manufacturers in/associated with such industries as:

- Aerospace

- Automotive

- Military Defense

- Natural Resources

- Medical Instruments

- Heavy Equipment Manufacturing

For additional information on the benefits of utilizing the multi-axis CNC gun drilling services offered by Noble Precision, visit our Gun Drilling page.

Noble Precision’s multi-axis CNC gun drilling services can provide practical solutions to your complex precision manufacturing needs. Call the precision gun drilling experts from Noble Precision at 647-499-7569 or Contact us to learn more about our capabilities and discuss how we can best support your custom manufacturing needs.