Examining the Differences Between Hot-Chamber and Cold-Chamber Die Casting

What is Die Casting?

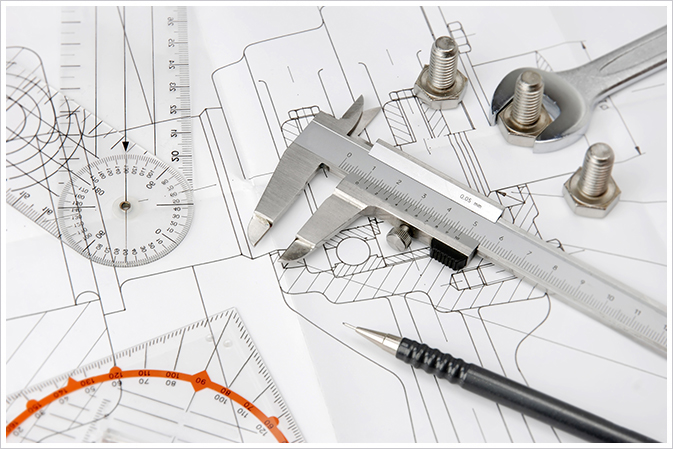

In the most basic terms, die casting is the process that involves the use of high pressure to force molten metal into a mold cavity to produce metal parts; these mold cavities are made of two hardened tool steel dies that are machined to conform to the specifications of the respective part or product. For optimum results, most die castings are manufactured from non-ferrous metals i.e., metals that do not contain iron to any appreciable amount.

There are essentially two types of die casting processes – hot-chamber and cold-chamber:

What is Hot-Chamber Die Casting?

Hot-Chamber Die Casting Process – a pool of molten metal is forced into the mold cavity via pressure applied by a pneumatic-powered or hydraulic-powered piston. The advantages of hot-chamber die casting include fast cycle times (up to 15 cycles per minute on average) and the convenience of melting the metal directly in the chamber/machine; a drawback to this process is its limitation to metals with low melting points only.

What is Cold-Chamber Die Casting?

Cold-Chamber Die Casting Process – use of this method requires the metal to be melted in a separate furnace then transported in precise amounts to the cold-chamber machine; this molten metal is then injected or shot into the mold by hydraulic or mechanical pistons. Use of the cold-chamber die casting process is ideal metals with high melting temperatures; its primary disadvantage is longer cycle times, due to the additional step of transferring the molten metal from a separate furnace to the machine.

As intimated above, the metal point or metal temperature of the respective metal dictates the type of die casting process that must be applied; a synopsis of the common metals most often used in each method would include:

- Hot-Chamber Die Casting

- Low melting-point metals/alloys – zinc, lead, magnesium

- Cold-Chamber Die Casting

- High melting-point metals/alloys – brass, copper, aluminum

In general, die casting is one of the most versatile metalworking processes; consequently, the use of die casting is common across a wide range of industries for the manufacturing of parts, components, and finished products in a variety of shapes and sizes.

Some examples of its application would include:

- Golf equipment

- Camera housings

- Electronic housings

- Locks and deadbolts

- Pumps and compressors

- Hospital bed control panels

- Dental workstation baseplates

It is important to note that few metalworking/manufacturing methods can be applied for all products or with all types of materials, and this relates to die casting as well; some of the limitations of the hot-chamber and cold-chamber die casting processes are the lack of cost-effectiveness for low-volume production runs and its diminished efficiency when the weight of a part or product exceeds 75 pounds.

Precision Molds for Optimal Results in Hot-Chamber and Cold-Chamber Die Casting

Many of the production efficiencies/benefits associated with either method of die casting are directly dependent on the accuracy and quality of the molds used in the specific processes. And while manufacturers might have the financial assets to invest in die casting equipment that can be used on a repeat basis, this may not be applicable to the one-time development of the actual mold or molds.

In order to achieve optimal benefits from their use of die casting, manufacturers might want to engage the mold-making expertise of the team at Noble Precision; these capabilities are supported by Noble Precision’s investment in state-of-the-art technology, specifically the latest in 5-axis simultaneous CNC machines and CAD/CAM software.

For further insight on the die casting services offered by Noble Precision, including precision mold making, see our die casting process page.

Call the precision mold making specialists from Noble Precision at 647-499-7569 today or contact us to request a complimentary consultation on our cutting-edge technologies and services and how we can support your hot-chamber and cold-chamber die casting needs.

Within the metal machining industry, the processes of metal removal and parts fabrication were once quite laborious; manually-operated equipment and multiple adjustments/set-ups were prevailing aspects in all production runs, resulting in time-consuming jobs and outputs that were less-than-precise on a repeatable basis.

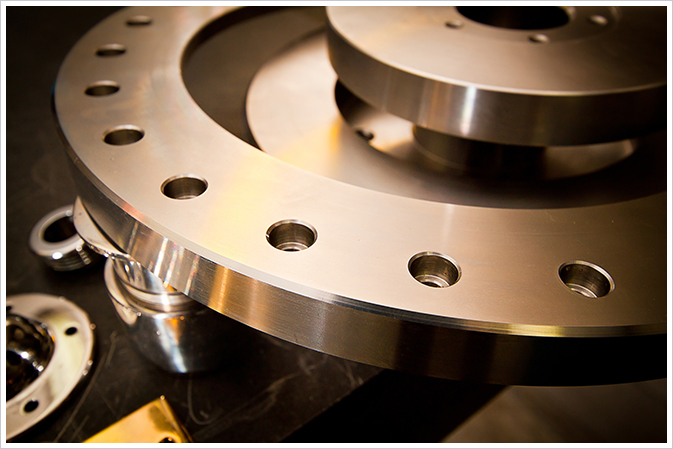

Within the metal machining industry, the processes of metal removal and parts fabrication were once quite laborious; manually-operated equipment and multiple adjustments/set-ups were prevailing aspects in all production runs, resulting in time-consuming jobs and outputs that were less-than-precise on a repeatable basis. Noble Precision, headquartered in Toronto, Canada, has made a substantial investment in this 5-axis simultaneous CNC machining technology as a commitment to meet and support the precision manufacturing needs of their clients.

Noble Precision, headquartered in Toronto, Canada, has made a substantial investment in this 5-axis simultaneous CNC machining technology as a commitment to meet and support the precision manufacturing needs of their clients. When performing some type of do-it-yourself home renovation project, many people have undoubtedly been frustrated by an inability to cut or shape their construction materials with a sufficient degree of accuracy; crown molding that does not meet precisely at a 90O angle, floor tiles that chip while being cut to size, and interlocking brickwork that will not properly interlock are just a few the countless examples that might have immediately come to mind. Consequently, while those jobs were still completed, they were likely not to the desired level of satisfaction.

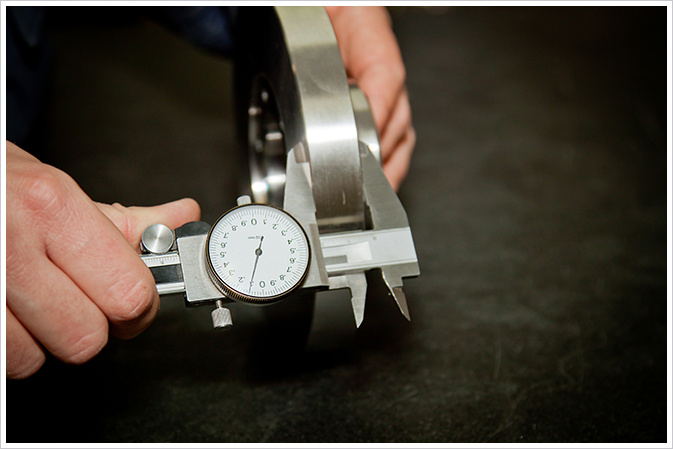

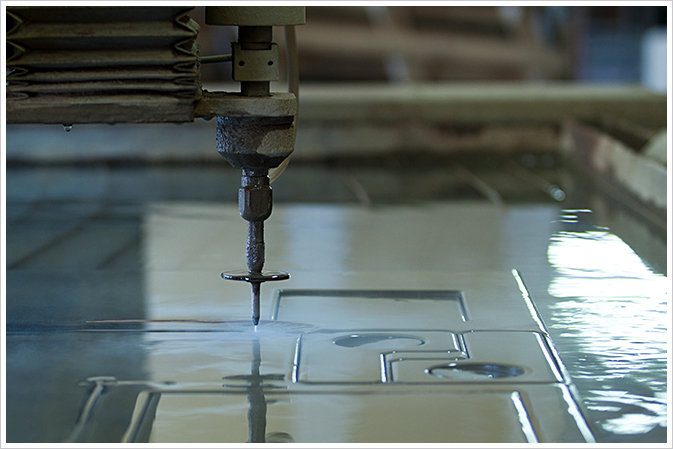

When performing some type of do-it-yourself home renovation project, many people have undoubtedly been frustrated by an inability to cut or shape their construction materials with a sufficient degree of accuracy; crown molding that does not meet precisely at a 90O angle, floor tiles that chip while being cut to size, and interlocking brickwork that will not properly interlock are just a few the countless examples that might have immediately come to mind. Consequently, while those jobs were still completed, they were likely not to the desired level of satisfaction. Noble Precision has made a significant investment in state-of-the-art 5-axis waterjet cutting technology, and the latest in associated CAD/CAM software, to provide clients with accurate and clean-edged cutting of complex parts and components from a wide variety of materials. In essence, 5-axis waterjet cutting technology allows more detailed cuts to be made than traditional three-dimensional methods (x, y, and z axes) via a synchronized or simultaneous movement around two rotational axes as well (a and b planes).

Noble Precision has made a significant investment in state-of-the-art 5-axis waterjet cutting technology, and the latest in associated CAD/CAM software, to provide clients with accurate and clean-edged cutting of complex parts and components from a wide variety of materials. In essence, 5-axis waterjet cutting technology allows more detailed cuts to be made than traditional three-dimensional methods (x, y, and z axes) via a synchronized or simultaneous movement around two rotational axes as well (a and b planes). In the most basic of terms, blow molding is a process used in the manufacturing of hollow plastic parts. This production method is a successor, in a manner of speaking, to the art of glassblowing, and it has permitted the replacement of heavier and/or breakable glass parts with lighter and more durable items or components.

In the most basic of terms, blow molding is a process used in the manufacturing of hollow plastic parts. This production method is a successor, in a manner of speaking, to the art of glassblowing, and it has permitted the replacement of heavier and/or breakable glass parts with lighter and more durable items or components. Noble Precision has the capacity to design/produce precise blow molds for the production of parts/components in a wide variety of shapes and sizes. This expertise is reinforced by Noble Precision’s considerable financial investments in state-of-the-art technology, notably the latest in 5-axis simultaneous CNC machines and CAD/CAM software; this commitment allows their clients to benefit from the most advanced and accurate machining methodology.

Noble Precision has the capacity to design/produce precise blow molds for the production of parts/components in a wide variety of shapes and sizes. This expertise is reinforced by Noble Precision’s considerable financial investments in state-of-the-art technology, notably the latest in 5-axis simultaneous CNC machines and CAD/CAM software; this commitment allows their clients to benefit from the most advanced and accurate machining methodology.