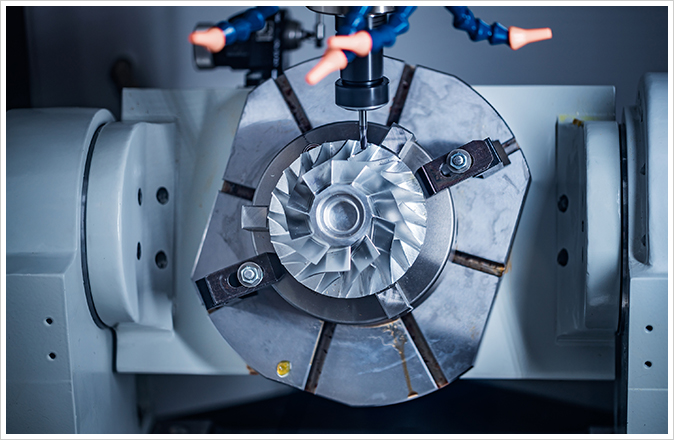

Technology has played a crucial role in the success of a manufacturing unit. Technical advancement leads to increased efficiency and reduced cost. Nobel Precision takes complete pride in using the latest 5-axis CNC simultaneous machine and domain expert team to provide the best solutions for all simple to complex manufacturing requirements.

CNC is abbreviation for Computer Numerical Control and such machines are electro-mechanical contrivances that handle machine shop tools using computer programming inputs. In simple terms, a CNC machine converts the design produced by the CAD (Computer Aided Design) software into numbers. The numbers can be considered as coordinates of a graph and they control the movement of the cutter, in contrast to the machines which are manually controlled by levers.

The first CNC machine was invented during 1940-50. Initially, it used a common telecommunication data storage technology (punched type). Very soon, it was taken over by the digital processing.

The CNC machine includes a mini computer which acts as the controller unit of the machine. The commands are directly entered into the computer through a small board similar to the traditional keyboard. The programs that are fed in can be used for different requirements with slight modifications based on the specifications.

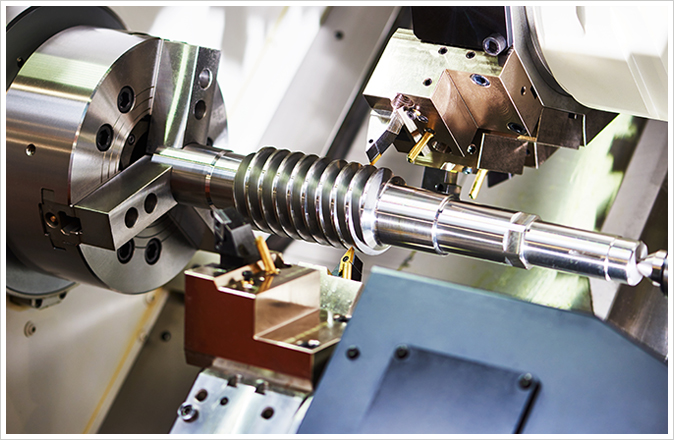

The CNC machine transforms a stock piece of material with the help of a controlled material removal process, resulting into a finished product. The digital instructions from a Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) file help in doing so. The CNC machine executes the design as per the stipulation for cutting prototype parts.

The capacity to program computer devices and administer the machine tools expeditiously enhances shop productivity. Moreover, automating the procedures simplifies the production, and abbreviates the dominance and involvement of physical work. Even for the most critical procedures the CNC machines result in perfect accuracy. With minimal operator efforts, the machines are designed well to meet perfection.

In order to produce a component or part, various tools are required such as drills, saws, etc. The traditional way uses different machines with some external help (operators) to move the component from machine to machine. Modern CNC machines often combine multiple tools into a single cell with limited extrinsic assistance. Movement is controlled along multiple axes, usually in the x-y axis, adding up a tool spindle that moves in the depth (z-axis), also rotationally about one or more axes, if required. The position of the tool provides extremely accurate movements. Multi-axis machines are proficient of capsizing parts over automatically, permitting the removal of the underneath material. This also reduces manual intervention to flip the prototype stock and cut all sides.

Fully automated cuts are more accurate than manual outputs. Competition and efficiency in the manufacturing units have increased the use of advanced technology with CNC machines.

Types of CNC Machines

CNC machines fall into two categories: conventional machining technology and novel machining technology. The former technology is used in drills, lathes, and milling machines. Electrical and/or chemical machining and other cutting mediums use the novel technology. The main purpose of these machines is to shape a particular metal.

Depending on the application, nearly any material can be used in a CNC machine. Common ones include aluminum, brass, steel, plastics, copper, wood, as well as fiberglass.

The Growing Market

The growth and use of CNC machines is directly proportional to the demand of efficient products. Automation systems and stimulation software being associated with these machines have definitely increased the production. Lathe machines dominate the global CNC market.

Integration of CNC and Automation

CNC machines are automated but still need assistance. If operated properly, they can work very well. The program parameters have to be set and thermal expansion of the machine should be monitored. Latter can help anticipate tolerance but operators need to regulate warning indicators and execute measurements on the tool after the machining procedures are accomplished. They might also need to change the tool, if required.

Today, CNC machines are exploiting from automation to produce accurate components. In current CNC systems, the design of a mechanical part and its manufacturing program is eminently automated. The part’s mechanical facets are elucidated using the CAD (Computer-Aided Design) software and then translated into manufacturing commands by CAM (Computer-Aided Manufacturing) software, transforming the resulting commands into particular instructions required for a specific machine to produce the component.

Noble Precision’s use of advanced technology and domain expert team have the capacity to accommodate the manufacturing of intricate and large-scale prototypes and components. With high-value production and state-of-the-art manufacturing techniques, quality and accuracy are prime features, resulting in affordable productions for all manufacturing units.

To further discuss our capabilities with respect to 5-axis simultaneous CNC machining, call Noble Precision today at 416-938-6455 or contact us to schedule a consultation on your specific precision manufacturing requirements.